Brief introduction

Virtually all of the restaurants’ French Fries we love use frozen product. There is substantial and growing market for frozen French fries which are made from fresh potatoes.

The global frozen potato market is projected to reach $74,403 million by 2025, registering a CAGR of 3.8% from 2018 to 2025. By product, French fries segment was the highest contributor to the global market and accounted for about 40% of the total global frozen potato market share. [ Frozen Potato Market Outlook – 2025]

Here, a process for preparing frozen French fried fries is introduced, potatoes are peeled, trimmed, cut into fries, blanched to translucency, dehydrated to remove surface moisture, par-frying, individual quick freezing (IQF) and then corresponding packaging and storage .

Raw potatoes

The properties of the potato are very important in producing idea French fries of good quality.

|

Size& shape |

Long or long oval tubers larger than 50 mm are ideal |

|

Moisture |

dry content of 20-24% |

|

Reducing suga |

not be more than 0.5% |

|

Specific gravity |

1.08 g/cm3 or more with 1.1 preferred |

Frozen French Fries Process Unit Operations

Potatoes size grading

In case the raw potatoes are not from professional supplier, potatoes should be graded by size before putting into producing schedule.

In one process, utilizing potatoes in one graded size is important. It will benefit an uniform potato fries size, consequently, allow for uniform cooking.

Small potatoes are not well suited for producing French fries due to yield a high proportion of short cuts and slivers.

Potato grader

Potato grader, in generally, is designed to size the various diameter potatoes in responding to different rollers gaps. The smallest potatoes are in the first selected and the largest is in the end discharging.

3 or 4 grading sized is in accordance with the processing scale volume.

Potatoes Peeling

Uniform size potatoes are feed into the hopper of an lifting conveyor , and then potatoes are transported to the potato peeler.

Brushing and abrasion peel removal is a common method for peeling potatoes. Potatoes duration in the peelers is the key point operation. Longer times will grind away much of the usable ingredient, creates a low yield.

Potato peeler

Softness and hardness brush rollers make potatoes peeling smoothly. Separate shower make a fine washing effect, small damage and more cleaning.

Trimming and Sorting

Peeled potatoes are conveyed in preparation for further processing. Unpeeled portions should be removed by trimming and those with serious defects are taken out of the processing lines.

Sorting and Trimming Table

It is designed to manual sort out the unacceptable potatoes and make trimming before slicing.

Staff working stations, collecting ducts combined a conveyor for trimming is depended on the processing scale.

Potato fries Slicing

The fat content in French fries decreases with increasing cross-section area of potato sticks, and rough surfaces increase the surface area and thus increase the fat absorption. Ideally, all potato sticks need to be cut to the same dimensions, with a fairly uniform cross section and, to a lesser extent, length to allow for uniform cooking (Blumentahl, 1991).

French fries slicer

French fries slicer is ability to orient the potatoes along the long axis, or as nearly so as possible, in order to obtain the greatest yield of long cuts. The size of French fries can be varied with various knife blocks, 3/8 or 1/2 inch in cross section are the most popular.

Fries Slivers Removal

Slivers and short pieces must be separate from the product following cutting into French fries. Otherwise, these unaccepted fries will result a burnt and dark color defects during par-frying.

Fries Slivers Removal Machine

Soft rollers with slots spaced to eliminate the slivers is used for this purpose.

Slice Rinsing

Surface starch that comes out of cut potato slices cause to stick together and colour unevenly. They should be removed by washing immediately.

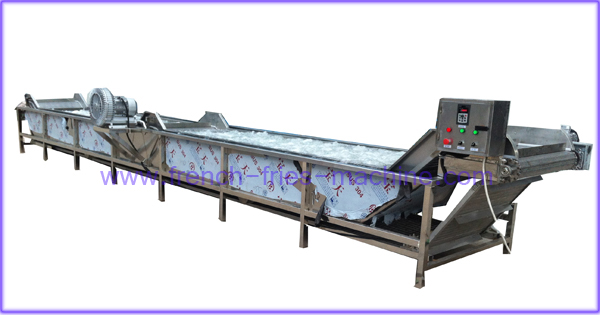

Potato frise rinsing machine

Rich bubbles from strong flow turbine fan make a flexible washing process.

High pressure spray shower which uses fresh water will wash again to have a final cleaning efficiency. The nozzle Angle is adjustable.

Blanching

Blanching is a processing step whereby potatoes are heated in steam or water for 2 to 3 min. This inactivates enzymes and prolongs the storage life of frozen fries. Moreover, blanching reduces the subsequent cooking time. Blanching also makes the colour more uniform after frying and it forms a layer of gelatinized starch that limits oil absorption and improves texture (Moreira, 1999).

The operation standard is that the potato fries are blanched until have a generally translucent throughout.

Potato fries blancher

Steam is recommended as heating source, it is economic and heating up quickly, the heat is uniform and the temperature difference is small. Thermal oil or electric heating is option.

Blanching temperature and time is set up easily and the mesh conveyor speed is adjustable to meet continuous blanching process.

Cover with water seal device to avoid steam leak, all body shell is filling with insulations, energy saves.

Cooling

Blanching care must be exercised for both under blanched which will turn off color due to enzymes not inactivated and over blanched which may slough the surfaces. Cooling process is the best way to stop blanching immediately in order to avoid over blanching.

Two stage cooling machine

Fresh water is used as the medium, 1st is pre-cooling and 2nd is deep cooling process.

Fresh water overflow from pre-cooling tank is collected and reused after cooling tower if necessary, while, flow over from 2nd cooling tank will be the back flow to 1st by water pump after filling. Air bubbles are supplied both for 1st and 2nd tank to solve the problem of water temperature stratification, ensure a quick cool with few fresh water consumption.

Dehydration

Surface moisture should be removed from the strips to reduce the load on the fryer and to minimize the rate of hydrolytic breakdown of the fat. The less water quantity evaporated, the short time frying takes. and consequently the lower the oil content of the French fries.

Vibrating dehydrator

It is a preliminary dehydration machine, removal the surface moisture quickly by means of shaking.

Overturn air dryer

Potato fries turn over continuously on the mesh during transport and touch the high pressure blowing air, special blowing blade design to remove or evaporate the extra water by means of air-drying from potato fries in a very short time.

Room temperature air drying with fan is sued in the first stage and hot air drying with fan is in the last stage mesh to ensure fully removing all the surface water. Hot air is heated by fin coil with electric heating.

Par-frying

By means of immersed in a deep fat fryer for a short period of time, around 15 to 60 seconds at a fat temperature of 300 F. to 375 F, The blanched potato strips are converted into the ready to cook French fries. Evaporation of water gives French fries crispy texture exterior while the inside of French fries is cooked.

The fat content of frozen French fries packed for retail trade is usually about 5 to 7 % and that of the par-fried product around 4 %.

Batch operation Deep fat fryer

Oil (Fat)-water mixture frying technology

Fried food residues are deposited into water throughout a mesh filter. Thus,

Frying oil pollution will be much reducer to result as long service lives and more clean.

Frying fat consumption is unexpected less as the fat in residues will be return to the frying oil before discharge.

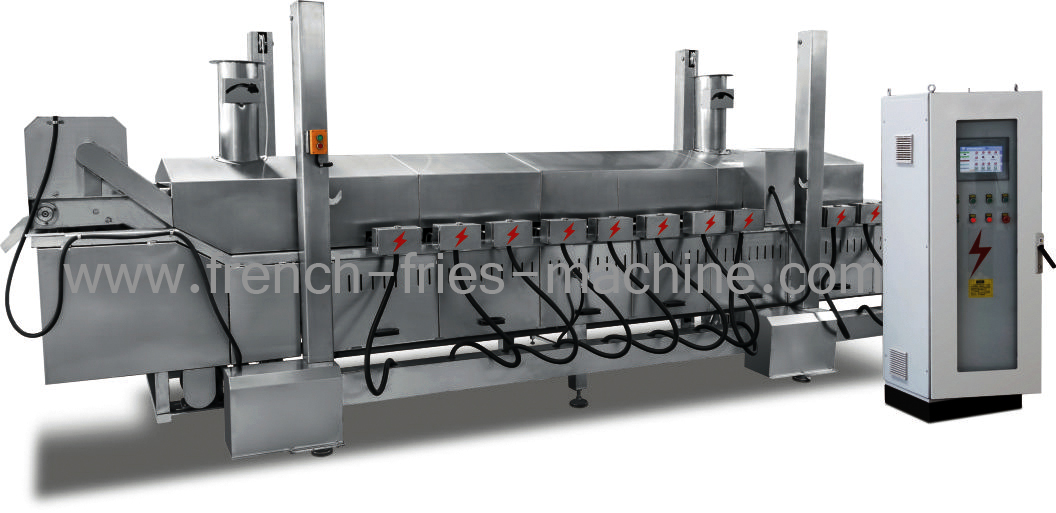

Continuous deep fat fryer

A standard continuous deep fat frying fryer includes:

1. an frying tank where the food is submerged in hot oil for frying process, equipped moving mesh belt conveyors and insulation shell ;

2. a gas fire or thermo-conductivity oil external heating unit if electric heating is not possible

3. an oil recirculation system, which pumps the oil through filters or/and external heaters if used and replenishes it from a bulk supply to maintain a steady volume in the frying tank.

4. an cover with exhaust system to remove the vapors emerging contains droplets of oil from the oil tank.

De-fating and Cooling

After deep fat frying, removing superficial fat should be done immediately while the oil temperature remains a high temperature, means of a low viscosity.

And then the par-fired potato fries should be cooled to be ready for the final step, a blast freezing

Vibrating De-fating machine

Shaking removing the surface oil quickly by means of vibrating motor and damping spring.

Air-cooling machine

Fried fries on the flat mesh are cooled by means of blowing air to remove the surface oil, and cool down to room temperature to meet the quick freezer feeding request in a short time.

Freezing is the one food process unit operation in which the temperature is reduced until its thermal center reaches −18 ℃, accompanied by the consequent crystallization of water. This results lowering the water activity (aw) of the food, inhibiting the spoilage by microorganisms and/or chemical reactions. [food science].

Blast freezing is a method that fluidized freezes the French Fries at -40 ℃ within 20 min in order to retain texture and to avoid damage as a result of ice crystal formation.

Machine

Fluidized bed air blast freezer

a modified Rapid Freezer, cold air is blown up through a wire mesh belt that conveys the particulate products such as peas, beans or shrimp. fluidization occurs. Each food comes in contact with air individually. Resulting a IQF (individually quick frozen) form. Freezing times commonly are in the order of minutes.