- Latest Updates Get Upto 45% Off, Grab The Best Deals

- cnhonesttrade@gmail.com

- Zhucheng Honest Industry & Trade Co.,Ltd

- Favorites

- Latest Updates Get Upto 45% Off, Grab The Best Deals

- cnhonesttrade@gmail.com

- Zhucheng Honest Industry & Trade Co.,Ltd

- Favorites

-

Autoclave Retort Sterilizer (5)

Autoclave Retort Sterilizer (5) -

Banana Chips Machine (6)

Banana Chips Machine (6) -

Cooking Kettle (7)

Cooking Kettle (7) -

Dehydration and Freezing in Food Preservation (1)

Dehydration and Freezing in Food Preservation (1) -

Freeze Dryer (2)

Freeze Dryer (2) -

Frozen French Fries Machines (5)

Frozen French Fries Machines (5) -

Garlic-Processing-Machine (2)

Garlic-Processing-Machine (2) -

Heat pump drying machine (12)

Heat pump drying machine (12) -

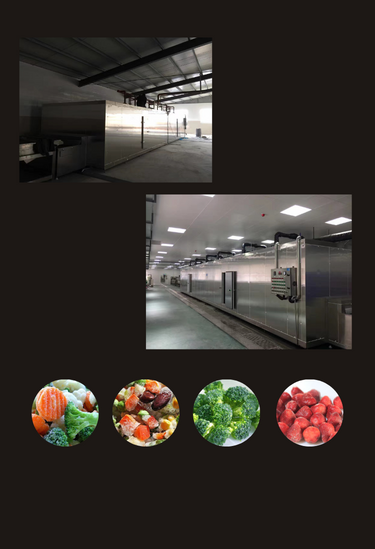

IQF (10)

IQF (10) -

Meat Processing Machine (11)

Meat Processing Machine (11) -

Onion-Processing-Machines (4)

Onion-Processing-Machines (4) -

Potato Chips French Fries Process Machine (10)

Potato Chips French Fries Process Machine (10) -

Potato Chips Potato Crisps Process Machines (3)

Potato Chips Potato Crisps Process Machines (3) -

Vacuum Cooling Machine (1)

Vacuum Cooling Machine (1) -

Vacuum Frying Machine (10)

Vacuum Frying Machine (10) -

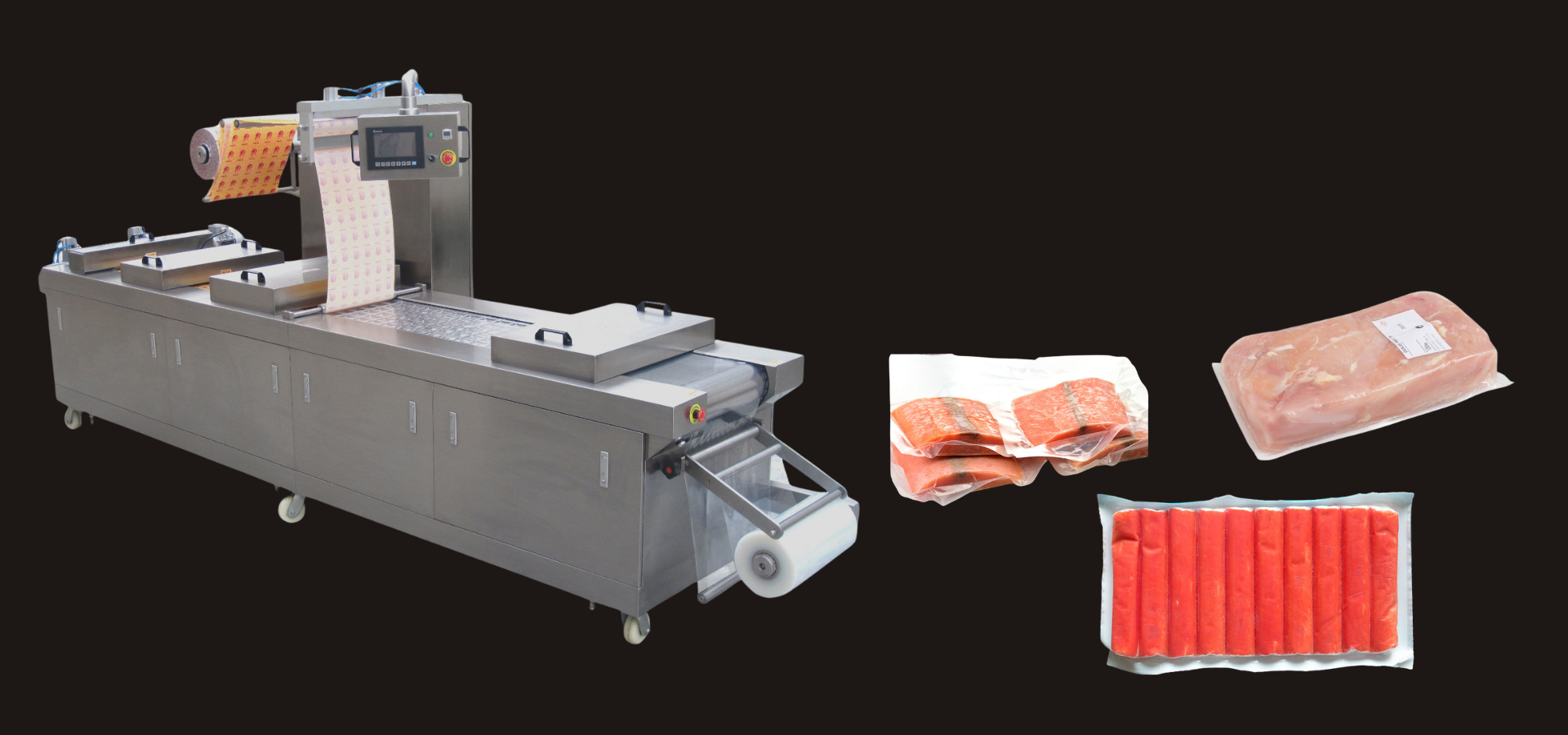

Vacuum Packaging Machine (11)

Vacuum Packaging Machine (11)

The Facilities Less Expensive

Innovating

The Heavy Fleets

-

Send Enquiry

Send Enquiry200kg/H Frozen Potato Fries Process Machines,Commercial Frozen Potato Strips Machines

Total PriceIncl. taxesThis machine list takes the 200kg/hr frozen potato fries process as an example, including potato peeler, potato fries slicer, potato strip blancher, hot air dryer, French fries par fryer and fluidized freezer. Machines for other industrial sale frozen potato fries process, like 300kg/hr,500kg/hr,1000kg/hr, 2000kg/hr is also avaiable in our supplying.

-

Send Enquiry

Send EnquiryA Crisp Fruit-Vegetable Chips Process With Vacuum Frying

Total PriceIncl. taxesA crisp fruit-vegetable chips process with vacuum frying is brief introduced, it is quick freeze process is necessary before vacuum frying in particular.

-

Send Enquiry

Send EnquiryA Short Review On Vacuum Frying-A Promising Technology For Healthier And Better Fried Foods

Total PriceIncl. taxesVacuum fried products contain lesser oil content, but this is not only the single health benefit of vacuum fried products. Lower operating temperature during vacuum frying; reduce 94% of acrylamide formation in potato chips. Acryl amide is recognized as a potential carcinogenic compound found in fried snacks, which is formed by the Maillard reaction.

-

Send Enquiry

Send EnquiryA Short View On Benefit And Drawback Of Various Quick Freezing Equipment Applications

Total PriceIncl. taxesThe frozen food tissue is influenced on freezing rate; the extent of damage depends on the size of the crystals and hence on the rate of heat transfers, means a flash freezing process.

-

Send Enquiry

Send EnquiryAgricultural Product Heat Pump Drying Versus Traditional Drying

Total PriceIncl. taxesWhy is heat pump drying popular in recent years? High efficiency, energy saving and low operating costs. The operating cost of heat pump drying is only 30% of the electric heating dryer, 40% of the fuel dryer, and 60% of the coal-fired dryer. The drying effect is good.

-

Send Enquiry

Send EnquiryAir Blast Fluidized Bed Freezer | Iqf Fluidized Freezer

Total PriceIncl. taxesFluidization frozen is an ideal way to achieve the IQF (Individually Quick Freezing), which is suitable for freezing the flakes, lumps, strip and granular vegetables with rapid freezing speed.

At French Fries Machines

At French Fries Machines

At French Fries Machines