Thermoforming Tray Packing Machine Brief Introduction

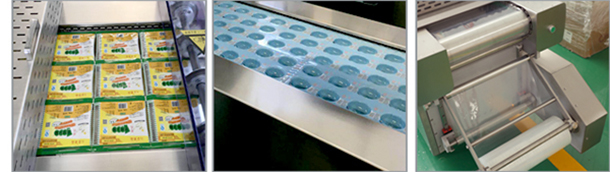

As one variety thermoforming vacuum packaging machine, automatic thermoforming tray packing machine is special designed to rigid container customized to your products and cover them with film, such as color printed plastic film, aluminium as well as a large variety of cover films to make them perfectly sealed.

Thermoforming rigid tray packaging machine is suitable for all kinds of pre-baked bread, cake and baked foodstuff fresh-keeping packaging.

One advantage is to thermoforming the rigid container directly by means of heating and stretching the film, not only saving the cost of prepared package but also avoids the secondary pollution.

Either vacuum packing only or gas flushing (MAP) packing process is available subjected to your products.

More packaging shapes and seals can be customized to make the packaging more attractive for sale.

Thermofored Rigid Tray Packaging Machine Features

- More variety film applicability

Wide-open chain is equipped for transmission which has the greater clamps strength, as a result, whether soft film, semi-hard film and hard film are all applicability.

Accurate servo control and optoelectronic tracking system ensures a high precision position of color film application.

- Perfect thermoforming

Either simple or complex rigid tray is easy thermoformed including precision side and corner.

- Flexible packing

Vacuum packing only or modified atmosphere packaging (MAP) operation is option.

- Precision cutting

Independent cross and longitudinal cutting is PLC controlled to carry out smooth trimming.

- Excellent vacuum pump

German food grade vacuum pump, Busch or Rietschile is standard supplying.

- Fast replace die sets

Fast, simple, easy changes for reducing die change times

- Trim recycling

A trim recycling system is equipped to maintain operation sanitation

- Easy to operate

Control with touchscreen, a user-friendly operation.

Option

Coding system

Thermoforming Tray Packing Machine Technical Data

| Item | Technical Data |

| Upper Film Width | 395mm |

| lower Film Width | 422mm |

| Vacuum | ≤200 Pa |

| Vacuum Rate | 100-300M3/h |

| Compreesed Air | ≥ 6 Bar |

| Cooling Water | ≥1.5 Ba |

| Power | 18Kw |

| Weight | 2200Kg |

| Dimension | 5300*950*1860mm |